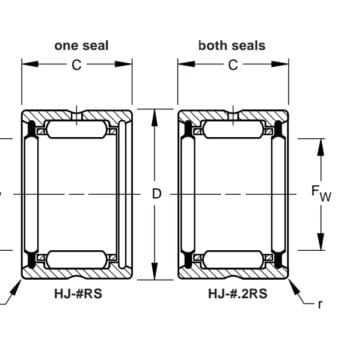

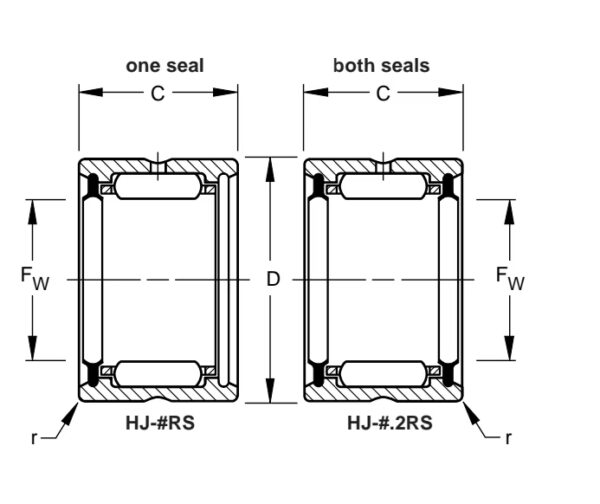

TIMKEN -Torrington HJ-283720.2RS with seals, Needle Roller bearing,Cylindrical Roller Radial Bearings-HJ-2RS Series 44,450X 58,738X 31,75 (mm)

Description

| Fw Bore (nom.) inch | 1.7500 |

| Fw Bore (nom.) mm | 44,450 |

| D Outside Diameter (nom.) inch | 2.3125 |

| D Outside Diameter (nom.) mm | 58,738 |

| C Width (nom.) inch | 1.250 |

| C Width (nom.) mm | 31,75 |

| § Limiting Speed | 2 200 |

| ra* Housing Fillet (max.) inch | 0.06 |

| ra* Housing Fillet (max.) mm | 1,5 |

| Used with Inner Ring Designation | IR-222820 IR-232820 IR-242820 |

DIMENSIONS AND LOAD RATINGS | |||||||||||||

| Fw Bore | D Outside Diameter | C Width | Bearing* Designation | Load Ratings | § Limiting Speed | ra* Housing Fillet | † Used with Inner Ring Designation | ||||||

| Basic Dynamic Cr

| Basic Static CO | ||||||||||||

| ISO | ISO | ||||||||||||

| (nom.) | (nom.) | (nom.) | T | 281 | 76 | (max.) | |||||||

| inch | mm | inch | mm | inch | mm | (with both seals) | lbf | lbf | lbf | rpm | inch | mm | |

| 0.6250 | 15,875 | 1.1250 | 28,570 | 1.000 | 25,40 | HJ-101816.2RS | 2 970 | 3 980 | 4 150 | 6 100 | 0.025 | 0,6 | — |

| 0.7500 | 19,050 | 1.2500 | 31,750 | 1.000 | 25,40 | HJ-122016.2RS | 3 170 | 4 250 | 4 680 | 5 100 | 0.04 | 1,0 | IR-081216 |

| 0.8750 | 22,225 | 1.3750 | 34,925 | 1.000 | 25,40 | HJ-142216.2RS | 3 540 | 4 750 | 5 600 | 4 400 | 0.04 | 1,0 | IR-101416 |

| 1.0000

| 25,400

| 1.5000

| 38,100

| 1.000

| 25,40

| HJ-162416.2RS

| 3 870

| 5 200

| 6 520

| 3 800

| 0.04

| 1,0

| IR-121616 IR-131616 |

| 1.1250

| 28,575

| 1.6250

| 41,275

| 1.250

| 31,75

| HJ-182620.2RS

| 5 740

| 7 700

| 11 200

| 3 400

| 0.04

| 1,0

| IR-141820 IR-151820 |

| 1.2500 | 31,750 | 1.7500 | 44,450 | 1.250 | 31,75 | HJ-202820.2RS | 5 900 | 7 920 | 11 900 | 3 100 | 0.04 | 1,0 | IR-162020 |

| 1.3750 | 34,925 | 1.8750 | 47,625 | 1.250 | 31,75 | HJ-223020.2RS | 6 290 | 8 430 | 13 300 | 2 800 | 0.04 | 1,0 | IR-182220 |

| 1.5000

| 38,100

| 2.0625

| 52,388

| 1.250

| 31,75

| HJ-243320.2RS

| 7 400

| 9 930

| 14 800

| 2 500

| 0.06

| 1,5

| IR-192420 IR-202420 |

| 1.6250

| 41,275

| 2.1875

| 55,562

| 1.250

| 31,75

| HJ-263520.2RS

| 7 600

| 10 200

| 15 700

| 2 400

| 0.06

| 1,5

| IR-212620 IR-222620 |

| 1.7500

| 44,450

| 2.3125

| 58,738

| 1.250

| 31,75

| HJ-283720.2RS

| 7 790

| 10 500

| 16 600

| 2 200

| 0.06

| 1,5

| IR-222820 IR-232820 IR-242820 |

| 2.0000

| 50,800

| 2.5625

| 65,088

| 1.250

| 31,75

| HJ-324120.2RS | 8 410

| 11 300

| 19 100

| 1 900

| 0.06

| 1,5

| IR-243220 IR-253220 IR-263220 IR-273220 |

| 2.2500 | 57,150 | 3.0000 | 76,200 | 1.750 | 44,45 | HJ-364828.2RS | 14 800 | 19 900 | 36 200 | 1 700 | 0.06 | 1,5 | IR-283628 |

| 2.5000

| 63,500

| 3.2500

| 82,550

| 1.750

| 44,45

| HJ-405228.2RS

| 16 000

| 21 500

| 41 300

| 1 500

| 0.08

| 2,0

| IR-314028 IR-324028 |

| 2.7500

| 69,850

| 3.5000

| 88,900

| 1.750

| 44,45

| HJ-445628.2RS

| 16 700

| 22 300

| 44 800

| 1 400

| 0.08

| 2,0

| IR-354428 IR-364428 |

| 3.0000

| 76,200

| 3.7500

| 95,250

| 1.750

| 44,45

| HJ-486028.2RS

| 17 700

| 23 800

| 49 900

| 1 300

| 0.08

| 2,0

| IR-384828 IR-404828 |

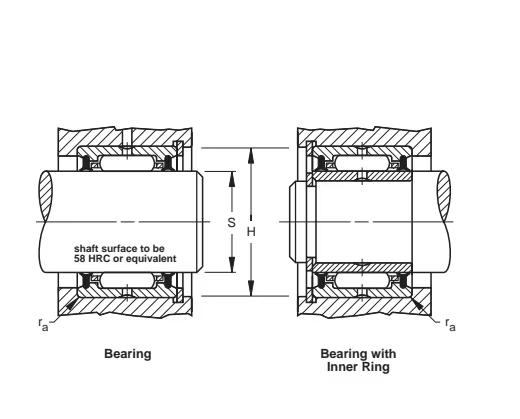

BEARING MOUNTING DIMENSIONS | ||||||||||||||||

| Mounting Dimensions, Clearance Fit | Mounting Dimensions, Tight Transition Fit | |||||||||||||||

| Inch Mounting | Metric Mounting(mm) | Inch Mounting | Metric Mounting(mm) | |||||||||||||

| S Shaft Raceway Diameter | H Housing Bore Diameter | S Shaft Raceway Diameter | H Housing Bore Diameter | Bearing Designation | S Shaft Raceway Diameter | H Housing Bore Diameter | S Shaft Raceway Diameter | H Housing Bore Diameter | ||||||||

| max. | min. | min. | max. | max. | min. | min. | max. | max. | min. | min. | max. | max. | min. | min. | max. | |

| 0.6250 | 0.6246 | 1.1250 | 1.1258 | 15,875 | 15,865 | 28,575 | 28,595 | -101816 | 0.6244 | 0.6240 | 1.1239 | 1.1247 | 15,860 | 15,850 | 28,547 | 28,567 |

| 0.7500 | 0.7495 | 1.2500 | 1.2510 | 19,050 | 19,037 | 31,750 | 31,775 | -122016 | 0.7492 | 0.7487 | 1.2487 | 1.2497 | 19,030 | 19,017 | 31,717 | 31,742 |

| 0.8750 | 0.8745 | 1.3750 | 1.3760 | 22,225 | 22,212 | 34,925 | 34,950 | -142216 | 0.8742 | 0.8737 | 1.3737 | 1.3747 | 22,205 | 22,192 | 34,892 | 34,917 |

| 1.0000 | 0.9995 | 1.5000 | 1.5010 | 25,400 | 25,387 | 38,100 | 38,125 | -162416 | 0.9992 | 0.9987 | 1.4987 | 1.4997 | 25,380 | 25,367 | 38,067 | 38,092 |

| 1.1250 | 1.1245 | 1.6250 | 1.6260 | 28,575 | 28,562 | 41,275 | 41,300 | -182620 | 1.1242 | 1.1237 | 1.6237 | 1.6247 | 28,555 | 28,542 | 41,242 | 41,267 |

| 1.2500 | 1.2494 | 1.7500 | 1.7510 | 31,750 | 31,735 | 44,450 | 44,475 | -202820 | 1.2490 | 1.2484 | 1.7487 | 1.7497 | 31,725 | 31,710 | 44,417 | 44,442 |

| 1.3750 | 1.3744 | 1.8750 | 1.8760 | 34,925 | 34,910 | 47,625 | 47,650 | -223020 | 1.3740 | 1.3734 | 1.8737 | 1.8747 | 34,900 | 34,885 | 47,592 | 47,617 |

| 1.5000 | 1.4994 | 2.0625 | 2.0637 | 38,100 | 38,085 | 52,388 | 52,418 | -243320 | 1.4990 | 1.4984 | 2.0610 | 2.0622 | 38,075 | 38,060 | 52,349 | 52,379 |

| 1.6250 | 1.6244 | 2.1875 | 2.1887 | 41,275 | 41,260 | 55,562 | 55,592 | -263520 | 1.6240 | 1.6234 | 2.1860 | 2.1872 | 41,250 | 41,235 | 55,524 | 55,554 |

| 1.7500 | 1.7494 | 2.3125 | 2.3137 | 44,450 | 44,435 | 58,738 | 58,768 | -283720 | 1.7490 | 1.7484 | 2.3110 | 2.3122 | 44,425 | 44,410 | 58,699 | 58,729 |

| 2.0000 | 1.9993 | 2.5625 | 2.5637 | 50,800 | 50,782 | 65,088 | 65,118 | -324120 | 1.9988 | 1.9981 | 2.5610 | 2.5622 | 50,770 | 50,752 | 65,049 | 65,079 |

| 2.2500 | 2.2493 | 3.0000 | 3.0012 | 57,150 | 57,132 | 76,200 | 76,230 | -364828 | 2.2488 | 2.2481 | 2.9985 | 2.9997 | 57,120 | 57,102 | 76,162 | 76,192 |

| 2.5000 | 2.4993 | 3.2500 | 3.2514 | 63,500 | 63,482 | 82,550 | 82,586 | -405228 | 2.4988 | 2.4981 | 3.2481 | 3.2495 | 63,470 | 63,452 | 82,502 | 82,538 |

| 2.7500 | 2.7493 | 3.5000 | 3.5014 | 69,850 | 69,832 | 88,900 | 88,936 | -445628 | 2.7488 | 2.7481 | 3.4981 | 3.4995 | 69,820 | 69,802 | 88,852 | 88,888 |

| 3.0000 | 2.9993 | 3.7500 | 3.7514 | 76,200 | 76,182 | 95,250 | 95,286 | -486028 | 2.9988 | 2.9981 | 3.7481 | 3.7495 | 76,170 | 76,152 | 95,202 | 95,238 |

The Timken-Torrington HJ-283720.2RS is a high-performance needle roller bearing with dual seals, designed for applications requiring robust load capacity, compactness, and protection from contaminants. This bearing is part of Timken-Torrington’s needle roller bearing range, commonly used in automotive, industrial machinery, and heavy equipment sectors where reliable performance and space efficiency are paramount.

Size and Weight:

The HJ-283720.2RS has a bore diameter of approximately 1.75 inches (44.45 mm), an outer diameter of 2.3125 inches (58.74 mm), and a width of 1.25 inches (31.75 mm). Its compact and lightweight structure makes it suitable for space-constrained applications, contributing to overall equipment design efficiency by allowing high load capacity without adding significant weight.

Performance:

This bearing is engineered with long, slender needle rollers made from high-grade, hardened steel, allowing it to handle high radial loads while maintaining minimal friction and wear. The dual seals (2RS) on both sides are designed to keep contaminants like dust, dirt, and moisture out of the bearing, while retaining lubricant inside. This ensures consistent performance, reduces maintenance frequency, and extends the bearing’s service life, even in challenging conditions or high-speed operations.

Usage:

The HJ-283720.2RS is ideal for applications where space is limited, yet high load capacity and protection from environmental contaminants are crucial. It is commonly used in automotive transmissions, industrial gearboxes, and various heavy-duty machinery. Its sealed design makes it particularly suitable for environments where contamination and lubricant leakage could compromise performance.

Structure:

The bearing features a robust cage that keeps the needle rollers evenly spaced, promoting stability and smooth operation under load. The dual rubber seals on both sides protect the internal components by preventing external contaminants from entering and retaining the lubricant within, which reduces noise, vibration, and wear during operation.

Overall, the Timken-Torrington HJ-283720.2RS needle roller bearing combines high load capacity, compact size, and superior sealing to deliver reliable performance in demanding applications. Its durable construction, protective seals, and efficient design make it a dependable choice for engineers seeking to optimize machinery performance in space-constrained and contamination-prone environments.