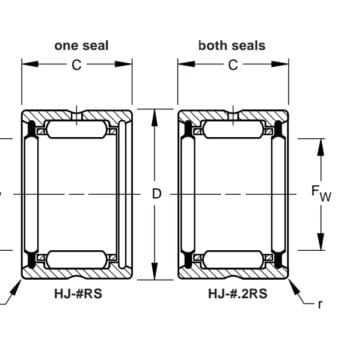

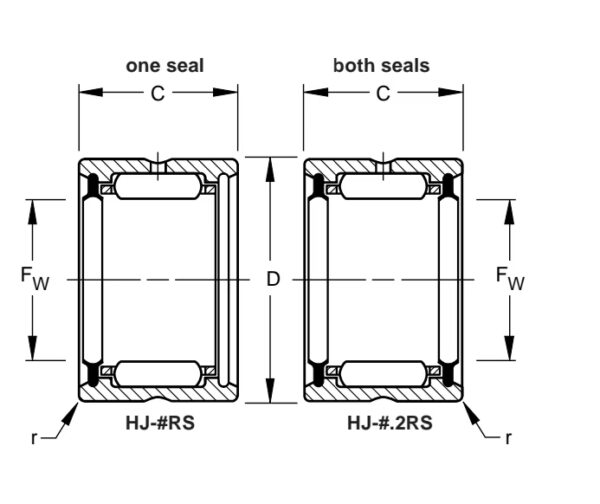

TIMKEN -Torrington HJ-486028.2RS with seals, Needle Roller bearing,Cylindrical Roller Radial Bearings-HJ-2RS Series 76,200 X 95,250 X 44,45 (mm)

Description

| Fw Bore (nom.) inch | 3.0000 |

| Fw Bore (nom.) mm | 76,200 |

| D Outside Diameter (nom.) inch | 3.7500 |

| D Outside Diameter (nom.) mm | 95,250 |

| C Width (nom.) inch | 1.750 |

| C Width (nom.) mm | 44,45 |

| § Limiting Speed | 1 300 |

| ra* Housing Fillet (max.) inch | 0.08 |

| ra* Housing Fillet (max.) mm | 2,0 |

| Used with Inner Ring Designation | IR-384828 IR-404828 |

DIMENSIONS AND LOAD RATINGS | |||||||||||||

| Fw Bore | D Outside Diameter | C Width | Bearing* Designation | Load Ratings | § Limiting Speed | ra* Housing Fillet | † Used with Inner Ring Designation | ||||||

| Basic Dynamic Cr

| Basic Static CO | ||||||||||||

| ISO | ISO | ||||||||||||

| (nom.) | (nom.) | (nom.) | T | 281 | 76 | (max.) | |||||||

| inch | mm | inch | mm | inch | mm | (with both seals) | lbf | lbf | lbf | rpm | inch | mm | |

| 0.6250 | 15,875 | 1.1250 | 28,570 | 1.000 | 25,40 | HJ-101816.2RS | 2 970 | 3 980 | 4 150 | 6 100 | 0.025 | 0,6 | — |

| 0.7500 | 19,050 | 1.2500 | 31,750 | 1.000 | 25,40 | HJ-122016.2RS | 3 170 | 4 250 | 4 680 | 5 100 | 0.04 | 1,0 | IR-081216 |

| 0.8750 | 22,225 | 1.3750 | 34,925 | 1.000 | 25,40 | HJ-142216.2RS | 3 540 | 4 750 | 5 600 | 4 400 | 0.04 | 1,0 | IR-101416 |

| 1.0000

| 25,400

| 1.5000

| 38,100

| 1.000

| 25,40

| HJ-162416.2RS

| 3 870

| 5 200

| 6 520

| 3 800

| 0.04

| 1,0

| IR-121616 IR-131616 |

| 1.1250

| 28,575

| 1.6250

| 41,275

| 1.250

| 31,75

| HJ-182620.2RS

| 5 740

| 7 700

| 11 200

| 3 400

| 0.04

| 1,0

| IR-141820 IR-151820 |

| 1.2500 | 31,750 | 1.7500 | 44,450 | 1.250 | 31,75 | HJ-202820.2RS | 5 900 | 7 920 | 11 900 | 3 100 | 0.04 | 1,0 | IR-162020 |

| 1.3750 | 34,925 | 1.8750 | 47,625 | 1.250 | 31,75 | HJ-223020.2RS | 6 290 | 8 430 | 13 300 | 2 800 | 0.04 | 1,0 | IR-182220 |

| 1.5000

| 38,100

| 2.0625

| 52,388

| 1.250

| 31,75

| HJ-243320.2RS

| 7 400

| 9 930

| 14 800

| 2 500

| 0.06

| 1,5

| IR-192420 IR-202420 |

| 1.6250

| 41,275

| 2.1875

| 55,562

| 1.250

| 31,75

| HJ-263520.2RS

| 7 600

| 10 200

| 15 700

| 2 400

| 0.06

| 1,5

| IR-212620 IR-222620 |

| 1.7500

| 44,450

| 2.3125

| 58,738

| 1.250

| 31,75

| HJ-283720.2RS

| 7 790

| 10 500

| 16 600

| 2 200

| 0.06

| 1,5

| IR-222820 IR-232820 IR-242820 |

| 2.0000

| 50,800

| 2.5625

| 65,088

| 1.250

| 31,75

| HJ-324120.2RS | 8 410

| 11 300

| 19 100

| 1 900

| 0.06

| 1,5

| IR-243220 IR-253220 IR-263220 IR-273220 |

| 2.2500 | 57,150 | 3.0000 | 76,200 | 1.750 | 44,45 | HJ-364828.2RS | 14 800 | 19 900 | 36 200 | 1 700 | 0.06 | 1,5 | IR-283628 |

| 2.5000

| 63,500

| 3.2500

| 82,550

| 1.750

| 44,45

| HJ-405228.2RS

| 16 000

| 21 500

| 41 300

| 1 500

| 0.08

| 2,0

| IR-314028 IR-324028 |

| 2.7500

| 69,850

| 3.5000

| 88,900

| 1.750

| 44,45

| HJ-445628.2RS

| 16 700

| 22 300

| 44 800

| 1 400

| 0.08

| 2,0

| IR-354428 IR-364428 |

| 3.0000

| 76,200

| 3.7500

| 95,250

| 1.750

| 44,45

| HJ-486028.2RS

| 17 700

| 23 800

| 49 900

| 1 300

| 0.08

| 2,0

| IR-384828 IR-404828 |

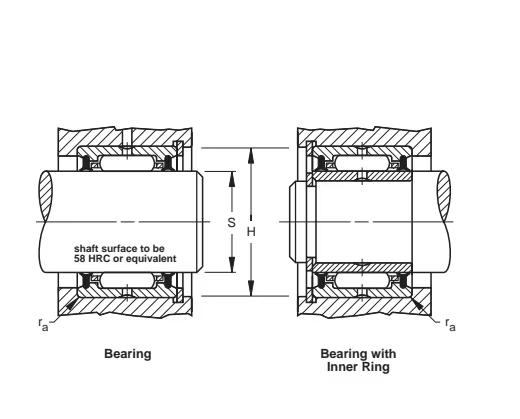

BEARING MOUNTING DIMENSIONS | ||||||||||||||||

| Mounting Dimensions, Clearance Fit | Mounting Dimensions, Tight Transition Fit | |||||||||||||||

| Inch Mounting | Metric Mounting(mm) | Inch Mounting | Metric Mounting(mm) | |||||||||||||

| S Shaft Raceway Diameter | H Housing Bore Diameter | S Shaft Raceway Diameter | H Housing Bore Diameter | Bearing Designation | S Shaft Raceway Diameter | H Housing Bore Diameter | S Shaft Raceway Diameter | H Housing Bore Diameter | ||||||||

| max. | min. | min. | max. | max. | min. | min. | max. | max. | min. | min. | max. | max. | min. | min. | max. | |

| 0.6250 | 0.6246 | 1.1250 | 1.1258 | 15,875 | 15,865 | 28,575 | 28,595 | -101816 | 0.6244 | 0.6240 | 1.1239 | 1.1247 | 15,860 | 15,850 | 28,547 | 28,567 |

| 0.7500 | 0.7495 | 1.2500 | 1.2510 | 19,050 | 19,037 | 31,750 | 31,775 | -122016 | 0.7492 | 0.7487 | 1.2487 | 1.2497 | 19,030 | 19,017 | 31,717 | 31,742 |

| 0.8750 | 0.8745 | 1.3750 | 1.3760 | 22,225 | 22,212 | 34,925 | 34,950 | -142216 | 0.8742 | 0.8737 | 1.3737 | 1.3747 | 22,205 | 22,192 | 34,892 | 34,917 |

| 1.0000 | 0.9995 | 1.5000 | 1.5010 | 25,400 | 25,387 | 38,100 | 38,125 | -162416 | 0.9992 | 0.9987 | 1.4987 | 1.4997 | 25,380 | 25,367 | 38,067 | 38,092 |

| 1.1250 | 1.1245 | 1.6250 | 1.6260 | 28,575 | 28,562 | 41,275 | 41,300 | -182620 | 1.1242 | 1.1237 | 1.6237 | 1.6247 | 28,555 | 28,542 | 41,242 | 41,267 |

| 1.2500 | 1.2494 | 1.7500 | 1.7510 | 31,750 | 31,735 | 44,450 | 44,475 | -202820 | 1.2490 | 1.2484 | 1.7487 | 1.7497 | 31,725 | 31,710 | 44,417 | 44,442 |

| 1.3750 | 1.3744 | 1.8750 | 1.8760 | 34,925 | 34,910 | 47,625 | 47,650 | -223020 | 1.3740 | 1.3734 | 1.8737 | 1.8747 | 34,900 | 34,885 | 47,592 | 47,617 |

| 1.5000 | 1.4994 | 2.0625 | 2.0637 | 38,100 | 38,085 | 52,388 | 52,418 | -243320 | 1.4990 | 1.4984 | 2.0610 | 2.0622 | 38,075 | 38,060 | 52,349 | 52,379 |

| 1.6250 | 1.6244 | 2.1875 | 2.1887 | 41,275 | 41,260 | 55,562 | 55,592 | -263520 | 1.6240 | 1.6234 | 2.1860 | 2.1872 | 41,250 | 41,235 | 55,524 | 55,554 |

| 1.7500 | 1.7494 | 2.3125 | 2.3137 | 44,450 | 44,435 | 58,738 | 58,768 | -283720 | 1.7490 | 1.7484 | 2.3110 | 2.3122 | 44,425 | 44,410 | 58,699 | 58,729 |

| 2.0000 | 1.9993 | 2.5625 | 2.5637 | 50,800 | 50,782 | 65,088 | 65,118 | -324120 | 1.9988 | 1.9981 | 2.5610 | 2.5622 | 50,770 | 50,752 | 65,049 | 65,079 |

| 2.2500 | 2.2493 | 3.0000 | 3.0012 | 57,150 | 57,132 | 76,200 | 76,230 | -364828 | 2.2488 | 2.2481 | 2.9985 | 2.9997 | 57,120 | 57,102 | 76,162 | 76,192 |

| 2.5000 | 2.4993 | 3.2500 | 3.2514 | 63,500 | 63,482 | 82,550 | 82,586 | -405228 | 2.4988 | 2.4981 | 3.2481 | 3.2495 | 63,470 | 63,452 | 82,502 | 82,538 |

| 2.7500 | 2.7493 | 3.5000 | 3.5014 | 69,850 | 69,832 | 88,900 | 88,936 | -445628 | 2.7488 | 2.7481 | 3.4981 | 3.4995 | 69,820 | 69,802 | 88,852 | 88,888 |

| 3.0000 | 2.9993 | 3.7500 | 3.7514 | 76,200 | 76,182 | 95,250 | 95,286 | -486028 | 2.9988 | 2.9981 | 3.7481 | 3.7495 | 76,170 | 76,152 | 95,202 | 95,238 |

The Timken-Torrington HJ-486028.2RS is a high-performance needle roller bearing known for its exceptional load capacity, compact size, and reliable sealing. Designed to excel in demanding industrial applications, this bearing offers a combination of strength, precision, and durability, making it an ideal choice for various heavy-duty machinery and equipment. Here’s a detailed overview of its size, weight, performance, usage, and structure.

Size and Weight

The HJ-486028.2RS bearing is specifically designed to maximize load capacity within a compact footprint. It features a bore diameter, outer diameter, and width that are optimized for tight spaces while maintaining a robust load-bearing capability. The compact design of this bearing makes it suitable for applications where space constraints are a primary concern, allowing it to be easily integrated into smaller assemblies without compromising strength or functionality. The relatively low weight of the bearing, considering its load capacity, contributes to the overall efficiency of the machinery, as it helps reduce the total weight of the system, which is especially important in applications where minimizing weight is crucial, such as in automotive and aerospace industries.

Performance

The performance of the Timken-Torrington HJ-486028.2RS bearing is characterized by its ability to handle high radial loads efficiently. Its needle roller design includes precision-ground rollers that offer a larger contact surface area compared to conventional bearings, ensuring even load distribution and reducing stress on individual components. The “2RS” suffix indicates that the bearing is equipped with dual rubber seals, which provide robust protection against contaminants like dust, dirt, and moisture. These seals are critical for maintaining lubrication within the bearing, which is essential for reducing friction, minimizing wear, and extending the bearing’s operational life.

This bearing is capable of operating at high speeds with low friction, which enhances its overall efficiency and reduces energy consumption. Its high-speed performance, combined with its durability, makes it suitable for continuous operation in challenging environments. The HJ-486028.2RS is also designed to perform reliably across a wide temperature range, making it versatile for use in various industrial applications where extreme conditions are a factor.

Usage

The Timken-Torrington HJ-486028.2RS needle roller bearing is commonly used in a wide array of industries due to its robust performance characteristics. Typical applications include:

- Automotive Industry: This bearing is frequently used in automotive transmissions, gearboxes, and differential systems where space is limited, and high load capacity is essential.

- Industrial Machinery: The bearing is ideal for heavy-duty industrial equipment, such as conveyor systems, presses, and rolling mills, where it provides reliable performance under high loads.

- Aerospace: In aerospace applications, the bearing is used in critical components like actuators and landing gear systems, where precision and reliability are paramount.

Construction Equipment: It is employed in construction machinery such as excavators and cranes, where it must withstand heavy loads and harsh operating conditions.

Structure:

The structure of the HJ-486028.2RS includes an inner ring, an outer ring, needle rollers, and a cage to keep the rollers uniformly spaced. The inner and outer rings are made from high-quality, heat-treated steel, which provides excellent durability and wear resistance. The needle rollers are precisely ground to ensure smooth operation and efficient load distribution, contributing to the bearing’s overall performance and longevity.

The bearing’s dual rubber seals are designed to prevent the ingress of contaminants and retain lubrication, which is crucial for maintaining optimal performance. These seals enhance the bearing’s ability to operate in environments with exposure to dust, dirt, or moisture, making it highly reliable in applications where contamination could otherwise pose a significant problem.

Overall, the Timken-Torrington HJ-486028.2RS needle roller bearing offers a balanced combination of compact size, high load capacity, and excellent sealing, making it a versatile and reliable component for a wide range of industrial and mechanical applications. Its robust design and superior performance ensure that it can handle the demands of heavy-duty operations, providing long-lasting service with minimal maintenance requirements.